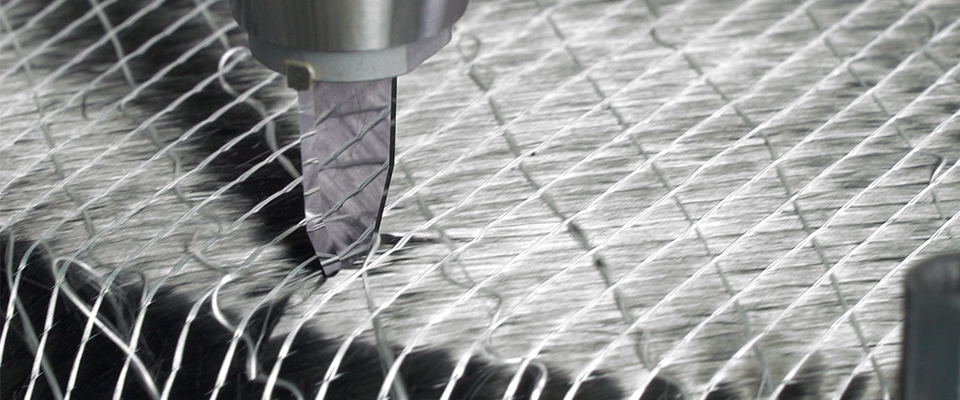

Cutting sonotrodes

High-strength materials

Advantages at a glance

- Use in automation or manual work station

- Suitable for high-strength or tough materials

- Low blade wear

- Reduction of the cutting force to be applied

- Clean cross-section

Sonotrodes

Sonotrodes are ultrasonic welding tools that are made to resonate when high-frequency mechanical oscillations are introduced. Sonotrodes are designed based on the Finite Element Method (FEM), and therefore guarantee optimum oscillation behaviour and long service life in all cases. The advantage of these sonotrodes is that the booster is already integrated and it does not need to be ordered. Boosters are used to increase or decrease the amplitude.

The Telsonic sonotrodes are available in Lambda 1 and Lambda 1/2. The application and accessibility determine the length that is used.

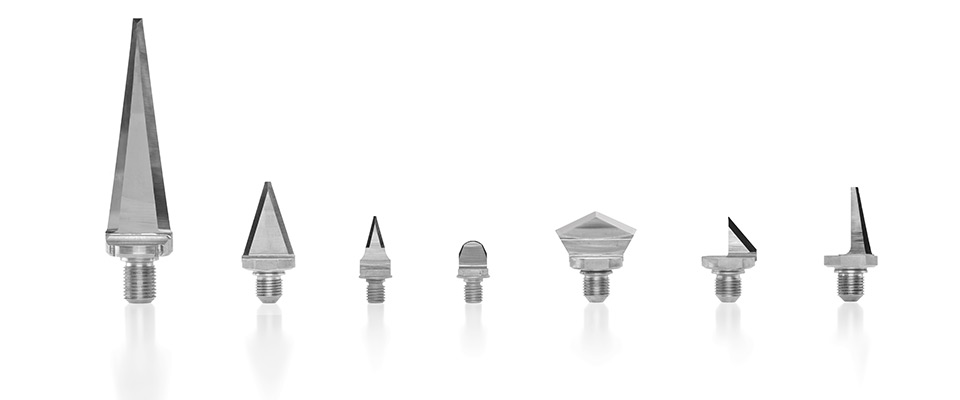

Knife tips

The knife tips that are manufactured from hard metal are screwed on to the sonotrode. This allows a knife change to be implemented very quickly.

The knife tips are available in different cutting lengths and shapes and are specially chosen for each application. The knife selection is dependent on the material to be cut, the thickness and whether radii are to be cut or not.

Characteristics and advantages

The ultrasonic cutting components are used in automation (robots) or with the HandyStar Energy